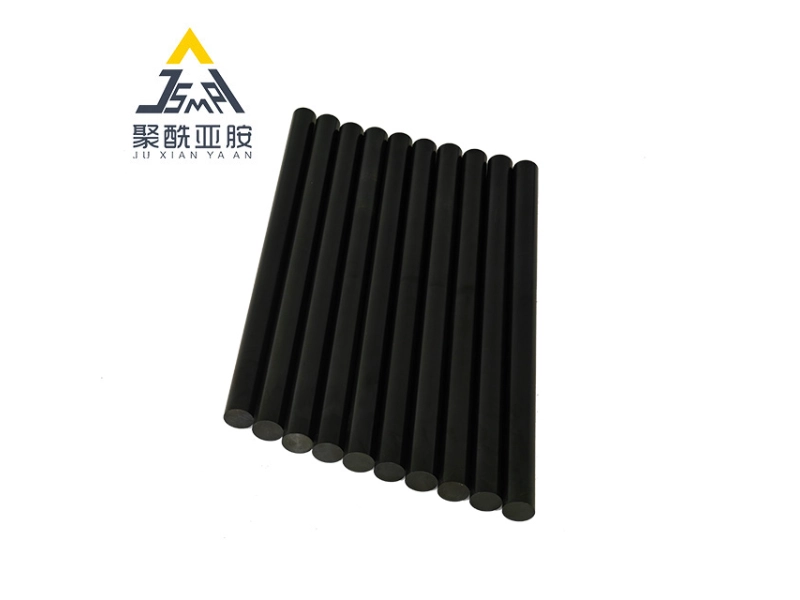

In recent years, the substances used in high-performance applications have experienced a significant transformation. One such material that has come forward as a revolutionary solution is electrically conductive polyimide resin rods. Known for their exceptional thermal stability and superb electrical conductivity, these rods are changing industries that demand reliability and performance. From cutting-edge manufacturing to state-of-the-art electronics, conductive polyimide resin rods are establishing themselves as vital components in modern technology.

Especially in the aerospace industry, where performance and safety are critical, the adoption of high-efficiency polyimide rods is gaining traction. These rods provide the necessary robustness and lightweight properties that are essential for aerospace applications, enabling the design of improved and durable aircraft components. As the need for advanced materials continues to rise, conductive polyimide resin rods stand at the forefront, offering exceptional advantages that help engineers push the boundaries of what is possible in aerospace design and beyond.

Overview of Conductive Polyimide Resins

Conductive materials have arisen as a vital material in multiple high-performance applications, particularly in sectors that demand exceptional thermal and electrical properties. Such materials are created through the polymerization of polyimide precursors, resulting in a robust material that not only exhibits substantial flexibility but also superb chemical resistance. Their special characteristics make them suitable for applications in environments where traditional materials may fail.

In the aerospace sector, conductive polyimide rods are crucial due to their ability to endure extreme temperatures while delivering electrical conductivity. Such attributes are essential for components that demand consistent performance in the face of thermal stress and fluctuating environmental conditions. The lightweight nature of polyimide resins contributes to the overall effectiveness of aircraft and spacecraft, making them a preferred choice for manufacturers focused on enhancing performance while reducing weight.

Furthermore, the flexibility of electrically-conductive polyimide resins allows for customization to meet specific operational requirements. By altering the composition and processing conditions, manufacturers can tailor these materials for specialized applications, ensuring optimal performance in fields spanning electronics to automotive and medical devices. As industries continue to innovate, the appetite for high-performance polyimide rods is expected to grow, driving developments in material science and engineering.

Applications in the Aerospace Industry

Conductive polyimide resin rods are progressively gaining traction in the aviation sector due to their lightweight properties paired with excellent thermal stability and mechanical strength. These rods are utilized in various components that require reliable electrical conductivity while maintaining the integrity of structural materials. The aerospace sector requires materials that can endure extreme temperatures and harsh operating conditions, making conductive polyimide an excellent choice for certain applications like insulation supports and brackets.

In addition to structural applications, electrically conductive polyimide rods have a vital role in the manufacturing of sensors and actuators utilized in aviation systems. Their ability to effectively transmit electrical signals while resisting damage from environmental factors places them as a favored material for key aerospace technologies. These rods ensure that the electronics onboard airplanes operate effectively, which is crucial for flight safety and performance.

Moreover, the lightweight nature of electrically conductive polyimide resin rods contributes to overall fuel efficiency in the aviation industry. By substituting heavier metal components with these high-performance rods, manufacturers can minimize the aircraft’s weight, leading to lower fuel consumption and reduced carbon emissions. This aligns with the aviation industry’s ongoing efforts to enhance sustainability while meeting the growing demands for performance and safety.

Advantages of Polyimide Resin Rods

Conductive polyimide resin rods offer exceptional thermal stability, making them perfect for applications in which high temperatures are a concern. Their ability to maintain physical properties at high temperatures allows them to be used in environments that other materials cannot withstand. This characteristic is particularly beneficial in the aerospace, in which components are often subjected to extreme heat during use.

Another significant advantage of polyimide resin rods is their outstanding electrical properties. These rods provide excellent conductivity while preserving a light structure, making them suitable for high-tech electronic applications. The mix of light weight and conductivity is essential in aerospace engineering applications, where every gram counts and efficient operation is important.

Additionally, polyimide rods exhibit remarkable chemical resistance and strength. They can withstand exposure to various substances without degrading, which ensures longevity and reliability in demanding environments. This robustness makes them an excellent choice for producing critical components in industries that require materials to perform under challenging conditions.

Future Developments and Advancements

The prospects of polyimide resin rods is encouraging, driven by advancements in engineering and engineering. As sectors increasingly demand light long-lasting, and high-performance components, these rods are set to assume a crucial role. Innovations in production processes, such as additive production and enhanced curing methods, are projected to enhance the qualities of these materials. This will lead to increased customizability, allowing for the creation of rods that satisfy particular operational needs in various challenging environments.

In the aviation sector, the push for greater efficiency and sustainable materials is prompting researchers to look into novel compositions of polyimide that integrate nanomaterials and other conductive additives. These innovations aim to improve not only conductivity but also thermal stability and mechanical strength. As the aviation field continues to seek reduced weight solutions without jeopardizing safety or performance, the role of high-performance polyimide rods in aircraft and spacecraft and space systems will expand significantly.

Outside of aviation, other industries such as the electronics industry and automobile manufacturing are beginning to see the potential of polyimide resin rods. https://bekker-huber.thoughtlanes.net/leveraging-your-power-of-electrically-conductive-polyimide-rods towards miniaturization and enhanced efficiency in devices aligns perfectly with the characteristics of these materials. Upcoming developments may also concentrate on integrating advanced technologies and smart sensors within conductive rods, allowing for the development of multi-purpose components that support advanced electronic technologies.