In recent years, the domain of material science has witnessed significant innovations that disrupt traditional paradigms. Among these innovations, conductive polyimide rods are becoming as a key player. These high-performance materials offer an impressive combination of electrical conductivity, thermal stability, and mechanical strength, making them perfect for a variety of demanding applications. Their special properties allow them to play a vital role in industries that require dependable and effective materials.

The aerospace industry, in particular, is poised to benefit significantly from the adoption of conductive polyimide rods. With the relentless pursuit of durable and lightweight components, these rods provide solutions that enhance the effectiveness and reliability of aircraft systems. From advanced electrical insulation to enhanced structural integrity, conductive polyimide rods are establishing their importance essential in advancing the frontiers of what's possible in aerospace engineering. As researchers and engineers keep examining the potential of these innovative materials, the future of material science looks exceptionally optimistic than ever.

Overview to Conductive-Enhanced Polyimide Rods

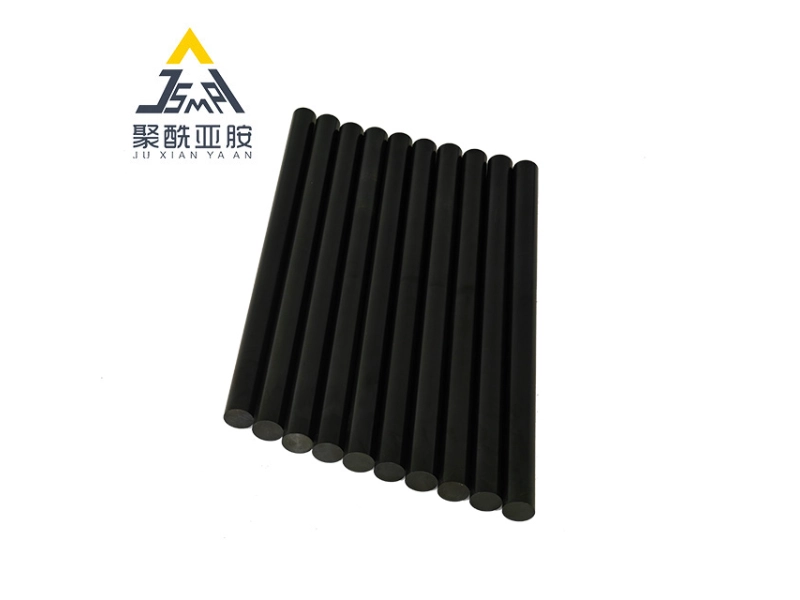

Electrically-Conductive polyimide rods are emerging as a innovative material in the area of substance science, because of their distinct mix of thermal stability, ability to conduct electricity, and robustness. These rods are produced from high-performance polyimide resin, which is recognized for its ability to endure severe temperatures while maintaining structural integrity. This makes them perfect for uses across diverse industries, particularly where protection and trustworthiness are paramount.

In the aerospace industry, conductive polyimide rods are becoming increasingly essential. They provide not only the necessary strength and toughness that aerospace applications demand but also the ability to carry electrical signals. This dual capability allows for new designs and methods in aircraft systems, where minimization of weight is vital and reliability is essential. The use of these rods can lead to significant advancements in efficiency and output, ultimately enhancing the protection and functions of aerospace machines.

Moreover, the flexibility of electrically-conductive polyimide rods extends past aerospace applications. With their outstanding electrical characteristics, they can be utilized in a variety of sectors, including automotive, electronics, and telecom. As material science develops, the ability of electrically-conductive polyimide rods to integrate multiple characteristics into a single product positions them as a revolutionary element in the evolution of innovative materials.

Applications in Aerospace Industry

Conductive polyimide rods are increasingly being implemented in the aerospace industry due to their exceptional thermal and mechanical properties. https://animefog3.bravejournal.net/a-destiny-of-electronics-investigating-conductive-type-polyimide-resin maintain their integrity and functionality even yet in extreme temperatures and environments, making them suitable for multiple aerospace components. Their lightweight nature contributes to lowered aircraft weight, leading to improved fuel efficiency and overall effectiveness.

In the engineering of aircraft and spacecraft, the need for consistent electrical insulation and conduction is crucial. Conductive polyimide rods serve a multiple purpose by providing both electrical conductivity and superior thermal insulation. This unique combination allows for the effective management of electrical systems on board, which is essential for the operation of avionics, sensors, and communication equipment. As the aerospace industry moves forward to embrace advanced materials, conductive polyimide rods surface as a crucial player in improving system reliability.

Moreover, these rods are highly resistant to external factors like moisture, radiation, and chemical exposure, which are typical challenges in aerospace applications. Their durability helps in prolonging the lifespan of essential components and reducing maintenance costs. With https://gray-falcon-pq33h2.mystrikingly.com/blog/conductive-polyimide-resin-rods-uses-in-advanced-technologies increasing emphasis on developing lightweight materials in aerospace design, conductive polyimide rods are changing how we approach functionality in this challenging field.

Benefits of Advanced Materials

Advanced composites, such as highly conductive polyimide rods, offer remarkable properties that make them ideal for a variety of utilizations. One key advantage is their exceptional temperature tolerance. These composites can withstand high temperatures without compromising their structural integrity, making them suitable for environments that experience intense heat fluctuations. This temperature stability leads to improved durability and longevity, which is crucial in industries like space exploration where material failure can have disastrous consequences.

Another noteworthy benefit is their lightweight nature. Electrically conductive polyimide rods provide an excellent strength-to-weight ratio, allowing for decreases in overall system mass. This is particularly favorable in space exploration applications where every gram counts. By using more lightweight materials, engineers can improve fuel efficiency and overall performance of flying vehicles and spacecraft, leading to economic benefits and greater environmental sustainability.

Additionally, the conductivity of these polyimide rods opens up fresh possibilities for state-of-the-art electronics and sensor technologies. https://dotson-sejersen.hubstack.net/why-conductive-polyimide-rods-are-revolutionizing-the-field-of-material-science to facilitate electrical flow while upholding the fundamental advantages of polyimide, such as resistance to chemicals and physical robustness, allows for pioneering designs in electronic components. This combination of conductivity with high-performance characteristics enables the design of light, reliable systems that can improve functionality in demanding contexts across diverse industries.

Future of Materials Science with Conductive Polyimide Rods

The outlook of material science is increasingly being formed by the advancements in conductive polyimide rods. These high-quality materials are establishing new standards in multiple industries, particularly in the aerospace sector, where their lightweight yet durable properties are essential. As requirements for increasingly efficient and dependable components rise, polyimide rods are situated to meet these challenges with exceptional performance in extreme conditions, opening the way for innovative designs and applications in aircrafts and space vehicles.

Moreover, as we explore the integration of smart materials and electronic systems, conductive polyimide rods are becoming essential in the advancement of next-generation technologies. Their ability to conduct electricity while maintaining thermal stability opens doors to uses in flexible electronics, detection systems, and cutting-edge robotics. This combination of electrical conductivity and mechanical strength is a game alterer, permitting for the creation of devices that were previously thought impossible, thus propelling forward the field of material science.

As studies continues and production methods progress, we can anticipate even wider applications for conductive polyimide rods. Their adaptability and efficacy will likely lead to their implementation in industries beyond aerospace, such as automotive and healthcare technologies. As the quest for eco-friendliness and effectiveness grows, polyimide rods will have a significant role in creating eco-friendly solutions that do not compromise on performance, ensuring a promising future for materials science.